|

Search

|

|

only one

keyword search term per box

|

|

|

|

|

Categories

|

|

|

|

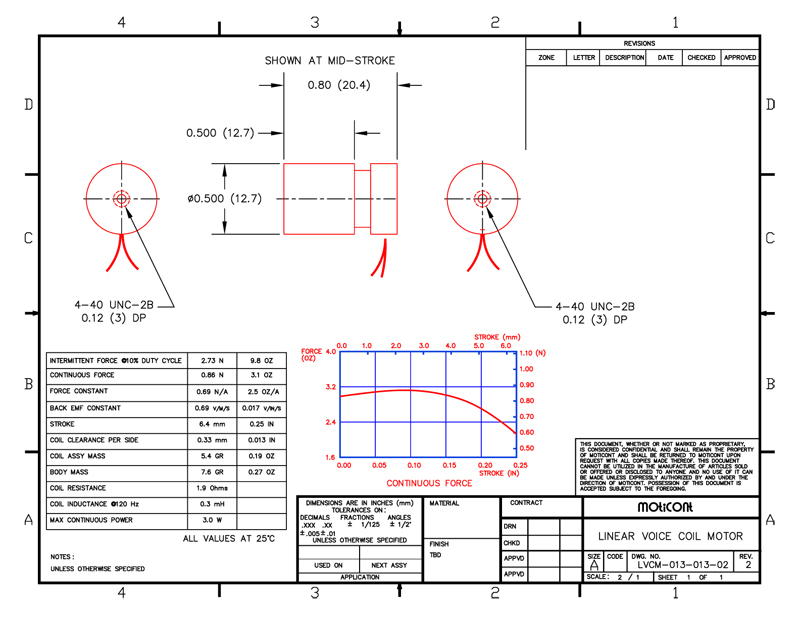

Linear DC Motor

item #: MOLDC01301302

Availability: in stock - available for immediate shipment

DC Linear Motor, Tubular, 0.50" (13 mm) DIA X 0.50" (13 mm) L

|

|

| Unit Price: | | | |

| 1-4 pieces: | $222.24 | | |

| 5-9 pieces: | $192.35 | | |

| 10-24 pieces: | $170.38 | | |

| 25-49 pieces: | $148.71 | | |

| 50-99 pieces: | $129.54 | | |

| Prices for larger quantities may be obtained by contacting us or by clicking the RFQ below. | | |

| OEM quantities, more than 100 units or special instructions: |

| | |

|